In the rapidly evolving landscape of industrial machinery, the quest for efficiency, sustainability, and cost-effectiveness has led to a significant breakthrough: the adoption of LiFePO4 (Lithium Iron Phosphate) lithium forklift batteries. These advanced power sources are not just a trend; they represent a paradigm shift in how forklifts are powered, offering unparalleled benefits that are transforming industrial operations globally.

1. The Shift from Traditional to Lithium: A Necessary Change

The industrial sector has long relied on traditional lead-acid batteries to power forklifts. These batteries, while functional, come with a host of limitations that can hinder operational efficiency. Lead-acid batteries are known for their lengthy charging times, limited cycle life, and the need for frequent maintenance, which can lead to increased downtime and operational costs.

As industries strive for greater efficiency and sustainability, the limitations of lead-acid batteries have become increasingly apparent. The lengthy charging times and limited cycle life of traditional batteries not only reduce operational efficiency but also contribute to higher costs and environmental impact. Moreover, the need for frequent maintenance of lead-acid batteries adds to the operational burden, diverting valuable resources away from core business activities.

The transition to LiFePO4 lithium batteries marks a significant shift in this narrative. These batteries offer a much faster charging time, longer lifespan, and lower maintenance requirements, making them an ideal choice for modern industrial operations. The rapid charging capability of LiFePO4 batteries allows for quick turnaround times, minimizing downtime and maximizing productivity. Furthermore, their extended cycle life translates to fewer battery replacements, reducing both operational costs and environmental impact.

Beyond performance, the environmental benefits of lithium batteries are noteworthy. They are more energy-efficient, with higher energy density and lower self-discharge rates compared to lead-acid batteries. This means they can store more energy and lose less of it when not in use, leading to reduced energy consumption and lower greenhouse gas emissions. Additionally, lithium batteries are more environmentally friendly to recycle, further contributing to their sustainability credentials.

2. LiFePO4 Battery Technology: Understanding the Core Advantages

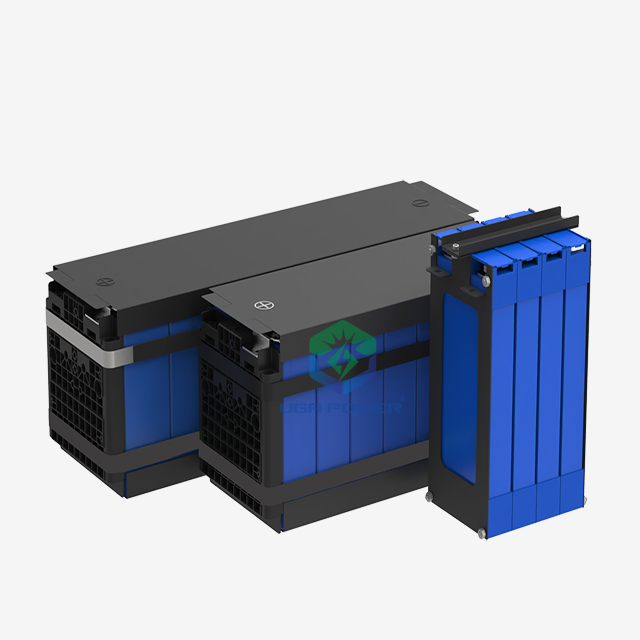

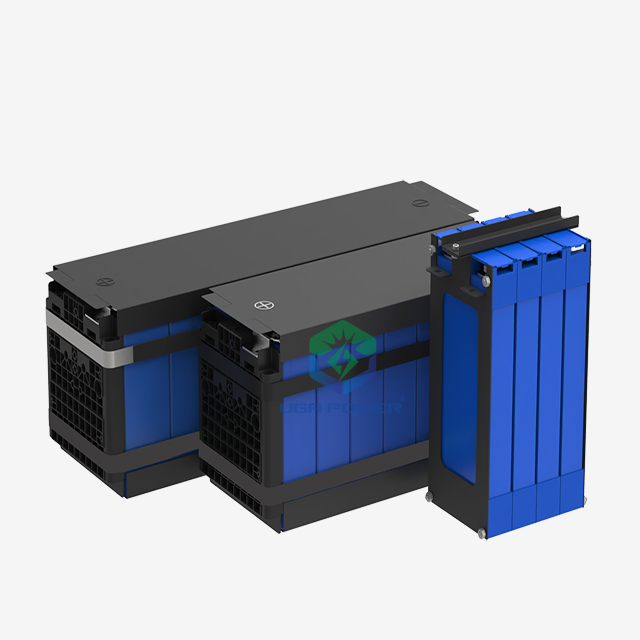

LiFePO4 battery technology is at the forefront of the lithium battery revolution, particularly in the context of industrial forklift applications. These batteries are characterized by their use of lithium iron phosphate as the cathode material, which offers several distinct advantages over traditional lead-acid batteries.

One of the most significant advantages of LiFePO4 batteries is their superior energy density. These batteries can store more energy in a smaller and lighter package, which is particularly beneficial for forklifts that require a lot of power but have limited space for batteries. This higher energy density translates to longer operating times between charges, reducing the need for frequent battery changes and allowing for more efficient use of the forklift.

The longer lifespan of LiFePO4 batteries is another key advantage. These batteries can last up to 10 times longer than traditional lead-acid batteries, with a cycle life of over 5,000 charge and discharge cycles. This longevity not only reduces the frequency of battery replacements but also lowers the overall cost of ownership, making lithium batteries a more cost-effective solution in the long run.

In terms of performance, LiFePO4 batteries excel in providing consistent power output, even at high discharge rates. This is crucial for forklifts that need to operate under heavy loads or in demanding conditions, as it ensures reliable performance and reduces the risk of power loss when the battery is under strain.

The fast charging capability of LiFePO4 batteries is another significant advantage. These batteries can be fully charged in as little as 1-2 hours, compared to the 8-12 hours required for lead-acid batteries. This rapid charging capability allows for more flexible and efficient use of the forklift, as it reduces downtime and allows for quick turnaround times.

In addition to their performance and efficiency benefits, LiFePO4 batteries are also more environmentally friendly than their lead-acid counterparts. They contain no toxic heavy metals and have a lower environmental impact throughout their lifecycle, from production to disposal. Furthermore, the higher energy efficiency of lithium batteries means they consume less energy during use, contributing to lower greenhouse gas emissions and a reduced carbon footprint.

3. Cost-Efficiency and Environmental Impact: A Dual Benefit

The adoption of LiFePO4 lithium forklift batteries brings about significant cost savings and environmental benefits that are hard to ignore. These advantages stem from the superior performance and efficiency of lithium batteries compared to traditional lead-acid batteries.

One of the most compelling reasons for the shift to lithium batteries is the substantial cost savings they offer. Although the initial investment in LiFePO4 batteries may be higher than that for lead-acid batteries, the long-term savings are significant. The extended lifespan of lithium batteries, often exceeding 5,000 charge cycles, means fewer battery replacements and lower maintenance costs. In contrast, lead-acid batteries typically require more frequent replacements and regular maintenance, which can add up to substantial costs over time.

The reduced downtime associated with lithium batteries also contributes to cost savings. The fast charging capability of LiFePO4 batteries means that forklifts can be quickly recharged during breaks, minimizing the need for spare batteries and reducing the overall operational costs. Additionally, the longer operating times between charges mean that forklifts can operate more efficiently, with less downtime for battery changes and maintenance.

From an environmental perspective, the benefits of lithium batteries are equally impressive. LiFePO4 batteries are more energy-efficient than lead-acid batteries, with higher energy density and lower self-discharge rates. This means they consume less energy during use and have a lower environmental impact throughout their lifecycle. Furthermore, lithium batteries contain no toxic heavy metals, making them more environmentally friendly to produce and recycle.

The reduced carbon footprint associated with lithium batteries is another significant environmental benefit. The higher energy efficiency of lithium batteries means they produce fewer greenhouse gas emissions during use, contributing to a lower carbon footprint for industrial operations. Additionally, the longer lifespan and lower maintenance requirements of lithium batteries mean less waste and fewer resources consumed over their lifecycle.

4. The Future of Industrial Operations: A Forklift Revolution

The revolution in industrial operations powered by LiFePO4 lithium forklift batteries is not just a trend; it’s a transformative shift that is here to stay. As industries continue to prioritize efficiency, sustainability, and cost-effectiveness, the adoption of lithium batteries is expected to accelerate, driven by their superior performance and environmental benefits.

The increasing adoption of LiFePO4 batteries across various industries is a clear indication of their growing acceptance and recognition as a reliable and efficient power source. Industries such as manufacturing, warehousing, logistics, and retail are all embracing lithium batteries for their forklifts, reaping the benefits of increased efficiency, reduced downtime, and lower operational costs.

The trend towards lithium-powered forklifts is also being driven by advancements in battery technology and decreasing costs. As lithium battery technology continues to evolve and improve, the performance and efficiency of these batteries are expected to increase, further enhancing their appeal for industrial applications. Additionally, as the production of lithium batteries scales up, the costs are expected to decrease, making them more accessible and affordable for a wider range of industries.

The future of industrial operations is undoubtedly bright with the adoption of LiFePO4 lithium forklift batteries. These batteries are revolutionizing the way industries operate, providing a reliable, efficient, and environmentally friendly power source for forklifts. As industries continue to prioritize sustainability and efficiency, the trend towards lithium-powered forklifts is expected to accelerate, paving the way for a greener and more efficient future for industrial operations.

5. Conclusion

The shift from traditional lead-acid batteries to LiFePO4 lithium batteries in forklifts is a game-changer for industrial operations. This transition is not just about upgrading equipment; it’s about embracing a more efficient, sustainable, and cost-effective way of powering industrial machinery. The benefits of lithium batteries are clear: they offer faster charging, longer lifespan, lower maintenance, and reduced environmental impact. For industries looking to optimize their operations and reduce their carbon footprint, the choice is clear. LiFePO4 lithium forklift batteries are the future of industrial power, and the time to make the switch is now.