Product Introduction

The LiFePO4 module for traction lithium battery is a cutting-edge energy solution designed for the most demanding industrial environments. Our lithium-ion traction batteries, including the 48V lithium forklift battery, 48V lithium traction battery, and lithium forklift battery, offer superior performance, efficiency, and safety compared to traditional lead-acid alternatives. These forklift lithium batteries are optimized for a wide range of applications, from electric forklifts to material handling equipment, providing seamless and reliable power to ensure smooth operations in warehouses, distribution centers, and manufacturing facilities.

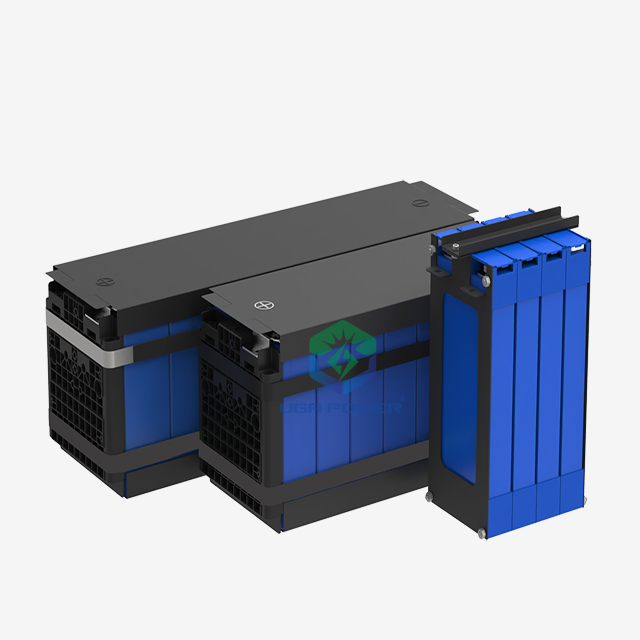

At the core of our lithium-ion traction battery lies a high-performance LiFePO4 module that offers long life cycles, faster charging times, and greater energy density. Unlike conventional battery types, lithium forklift batteries are known for their compact size and high energy output, delivering consistent power and requiring less maintenance. The modular design of the LiFePO4 module allows for flexibility and scalability, making it an ideal choice for various forklift battery configurations.

>Specification

| Voltage | Model | 48V200Ah | 48V300Ah | 48V400Ah | 48V500Ah | 48V600Ah |

| 48V series | Technical parameters | Rated capacity | 200Ah | 300Ah | 400Ah | 500Ah | 600Ah |

| Rated voltage | 51.2V |

| Battery energy | 10.24Kwh | 15.36Kwh | 20.48Kwh | 25.60Kwh | 30.72Kwh |

| Cell material | Lithium iron phosphate |

| Ingress protection | IP54 |

| Battery weight (kg) | 110 | 140 | 170 | 205 | 260 |

| Battery dimension (mm) | 600*220*635 | 600*300*635 | 600*380*635 | 600*460*635 | 600*545*635 |

| Charging | Rated charging current | 100A | 100A | 200A | 200A | 200A |

| Max. charging current | 100A | 150A | 200A | 200A | 300A |

| Charge status display | Displayed on the external display and charger |

| Charging time | 120–180 min |

| Maximum charging voltage | 57.6V |

| Charging temperature | 0°C to 55°C |

| Discharging | Discharge temperature | –10°C to 55°C |

| Rated discharge current | 100A | 100A | 100A | 100A | 100A |

| Maximum discharge current | 200A | 200A | 200A | 200A | 200A |

| Discharge cut-off voltage | 44.8V |

Product Advantage

The LiFePO4 module for traction lithium batteries comes with numerous advantages that set it apart from other power solutions in the market, making it the go-to choice for industries looking for efficiency and reliability.

1. Advanced Battery Management System (BMS)

One of the key benefits of our lithium forklift battery is its state-of-the-art Battery Management System (BMS). This advanced system is built to military-grade standards, ensuring optimal performance and safety throughout the battery's lifecycle. The BMS includes:

Over-current protection: Prevents the battery from excessive power flow, protecting both the battery and the equipment.

Over-discharge protection: Ensures the battery does not discharge beyond its safe limits, extending battery life.

Over-charge protection: Automatically shuts off charging once the battery is fully charged, preventing damage.

Short-circuit protection: Safeguards the battery and connected equipment from electrical faults.

Reverse polarity connection protection: Prevents damage if the battery is mistakenly connected the wrong way.

Cell balancing: The BMS ensures each cell in the battery pack remains balanced, preventing any one cell from becoming overcharged or over-discharged, which can lead to reduced performance and battery life.

2. Precision Welding and Premium Assembly Materials

The assembly of our lithium forklift battery involves precision welding and the use of premium assembly materials to ensure the highest quality and reliability. Every battery pack is meticulously spot-welded using automated welding processes, which ensures minimal energy consumption and maximum strength.

Nickel sheets and high-quality wiring are selected for their ability to withstand high currents, ensuring a reliable and durable power source.

The use of premium materials increases the lifespan of the battery and reduces the frequency of maintenance, making it more cost-effective over time.

3. Fast Charging and Efficient Charging Infrastructure

The charging infrastructure for our 48V lithium forklift battery is designed to maximize efficiency. It includes:

High-frequency switching power supply: This power supply provides efficient energy conversion, allowing for quicker charging times without compromising safety.

Charging pile: This is designed to work seamlessly with the BMS, ensuring optimal charging performance.

Battery Management System: The BMS communicates with the charging pile to orchestrate the charging process, ensuring that the battery is charged safely and efficiently.

With this system in place, you can expect fast charging times and fewer downtime periods, making the lithium forklift battery a reliable solution for operations that require constant power.

4. Long Lifespan and Deep Cycle Capability

The LiFePO4 module offers deep cycle capability, meaning it can endure more charge and discharge cycles compared to traditional lead-acid batteries. This results in longer lifespan and reduced battery replacement costs over time. The deep-cycle nature of these batteries makes them ideal for industries that require forklift batteries to operate continuously for extended periods.

Product Uses

The LiFePO4 module for traction lithium battery is perfect for various industrial applications that demand a high-performance power source. Below are some of the key uses for this advanced battery technology:

1. Electric Forklifts

The 48V lithium forklift battery is widely used in electric forklifts, providing reliable power to keep your operations running smoothly. It supports 48V forklifts, ensuring consistent performance even in high-demand environments. Compared to traditional lead-acid forklift batteries, lithium forklift batteries are lighter, require less maintenance, and provide more power per charge, significantly improving productivity.

2. Material Handling Equipment

Our lithium forklift battery is also used in various other material handling equipment, such as pallet jacks, reach trucks, and order pickers. The 48V lithium traction battery ensures these machines operate with greater efficiency, reducing downtime and improving overall warehouse productivity.

3. Commercial and Industrial Vehicles

In addition to forklifts, the traction battery vs lithium-ion battery comparison shows that lithium-ion batteries can be adapted to power a wide range of electric vehicles, including trucks and other industrial vehicles. With a longer lifespan and deep cycle capability, these batteries are ideal for applications where truck battery solutions are needed for high-performance vehicles.

Product Operate Guide

Operating and maintaining your LiFePO4 module for traction lithium battery is straightforward, but following proper guidelines ensures you get the most out of your investment.

1. Charging the Battery

Charging the 48V lithium forklift battery is simple and efficient. The charging process is managed by the Battery Management System (BMS), which ensures the battery is charged safely and optimally. Here's how to get started:

Step 1: Connect the battery to the charging pile.

Step 2: Ensure the power supply is connected and operational.

Step 3: The BMS will automatically begin the charging process, adjusting parameters for optimal safety and performance.

Step 4: Once fully charged, the BMS will stop the charging process to prevent overcharging.

Important Note: Always ensure that the charging pile and power supply are in good condition to avoid any electrical faults.

2. Battery Maintenance

While lithium forklift batteries require minimal maintenance compared to traditional lead-acid batteries, it's important to follow these steps for proper upkeep:

Regular Inspection: Check the battery regularly for signs of wear or damage.

Clean the Battery: Use a dry cloth to clean the battery terminals and connections. Avoid using water or cleaning agents that could cause corrosion.

Ensure Proper Storage: If the battery is not in use for an extended period, store it in a cool, dry place with a full charge. This will help prolong the battery’s lifespan.

3. Safety Guidelines

Safety is paramount when working with lithium forklift batteries. Follow these basic guidelines to ensure safe operation:

Avoid Overcharging or Over-Discharging: The BMS will protect the battery, but avoid pushing the battery to its limits for longevity.

Store Properly: Always store batteries in a cool, dry environment to prevent overheating or damage.

Monitor Temperature: If the battery becomes excessively hot during operation, stop using it immediately and allow it to cool down.

FAQ

Q1: What is the difference between a traction battery and a lithium-ion battery?

A1: A traction battery is specifically designed for industrial equipment like forklifts, offering high power and durability. Lithium-ion batteries, including lithium forklift batteries, are rechargeable and more efficient, providing longer lifespan and faster charging times compared to traditional batteries.

Q2: How does the Battery Management System (BMS) work in the LiFePO4 module?

A2: The Battery Management System (BMS) ensures safe operation by monitoring battery health, protecting against overcharging, over-discharge, and short-circuit, and balancing the cells for optimal performance. It works seamlessly with the charging pile for efficient charging.

Q3: What are the benefits of using a 48V lithium forklift battery?

A3: 48V lithium forklift batteries offer a longer lifespan, faster charging times, and lower maintenance compared to traditional lead-acid batteries. They also provide more consistent power, reducing downtime and operational costs.

Q4: How can I maintain my lithium forklift battery?

A4: To maintain your lithium forklift battery, inspect it regularly for damage, keep terminals clean, and store it in a cool, dry place. Ensure the battery is not overcharged and use the proper charging equipment to maximize lifespan.

Q5: Is the lithium forklift battery safe to use?

A5: Yes, the lithium forklift battery comes with advanced safety features such as over-current, over-discharge, and short-circuit protection, all managed by the Battery Management System (BMS), ensuring safe and reliable performance.