Product Introduction

The Lithium Ion Forklift Battery 24V series (available in 100AH, 200AH, 300AH, 400AH, and 500AH models) is a revolutionary power solution for industrial and commercial electric forklift applications. Designed to offer superior performance, long service life, and high energy efficiency, these batteries are ideal for demanding environments that require maximum uptime and reliability. Whether you're managing an electric forklift fleet or seeking a better solution for your e-trucks and e-traction vehicles, the Lithium Ion Forklift Battery provides a versatile and cost-effective energy storage system.

Unlike traditional forklift lead-acid batteries, our Lithium Ion Traction Battery offers faster recharging, higher energy efficiency, and a longer lifespan, making it an excellent choice for operations looking to optimize their material handling operations.

Product Advantage

1.Short and Quick Reloading

With the Lithium Ion Traction Battery, recharging becomes a breeze. You can recharge the battery even during short breaks, eliminating the need for time-consuming battery swaps or extended downtime. This feature ensures that your electric forklift or e-traction vehicle is ready to go in no time, providing a significant reduction in labor and operational costs.

2.Higher Energy Efficiency

The 24V Lithium Forklift Battery boasts a high energy density, delivering up to 30% more energy compared to traditional forklift battery types. This enhanced energy efficiency leads to more hours of operation with less power consumption, which helps reduce your total cost of ownership (TCO) and improve operational performance.

3.Powerful System

The Lithium Forklift Battery maintains optimal performance even as the charge level decreases. Unlike conventional lead-acid batteries, where performance drops significantly as the battery discharges, the Lithium Forklift Battery China provides steady power output throughout the entire charge cycle. This means your electric forklift or e-traction vehicle can perform at its peak even as the battery nears depletion, ensuring smooth and uninterrupted operations.

4.User-Friendly Solution

Safety and ease of maintenance are paramount when it comes to battery-powered systems. The Lithium Ion Traction Battery is designed with a maintenance-free approach, meaning no harmful acid leaks or battery gas emissions. This feature makes the battery safe to use in environments with stringent safety regulations, such as warehouses or manufacturing plants. Additionally, it’s easy to clean and maintain, significantly reducing the total cost of ownership and hassle for operators.

Specification

| Voltage | Model | 24V100Ah | 24V200Ah | 24V300Ah | 24V400Ah | 24V500Ah |

| 24V series | Technical parameters | Rated capacity | 100Ah | 200Ah | 300Ah | 400Ah | 500Ah |

| Rated voltage | 25.6V |

| Battery energy | 2.56Kwh | 5.12Kwh | 7.68Kwh | 10.24Kwh | 12.8Kwh |

| Cell material | Lithium iron phosphate |

| Ingress protection | IP54 |

| Battery weight (kg) | 42 | 58 | 74 | 90 | 110 |

| Battery dimension (mm) | 600*195*400 | 600*198*400 | 600*180*635 | 600*220*635 | 600*265*635 |

| Charging | Rated charging current | 50A | 100A | 100A | 200A | 200A |

| Max. charging current | 50A | 100A | 150A | 200A | 200A |

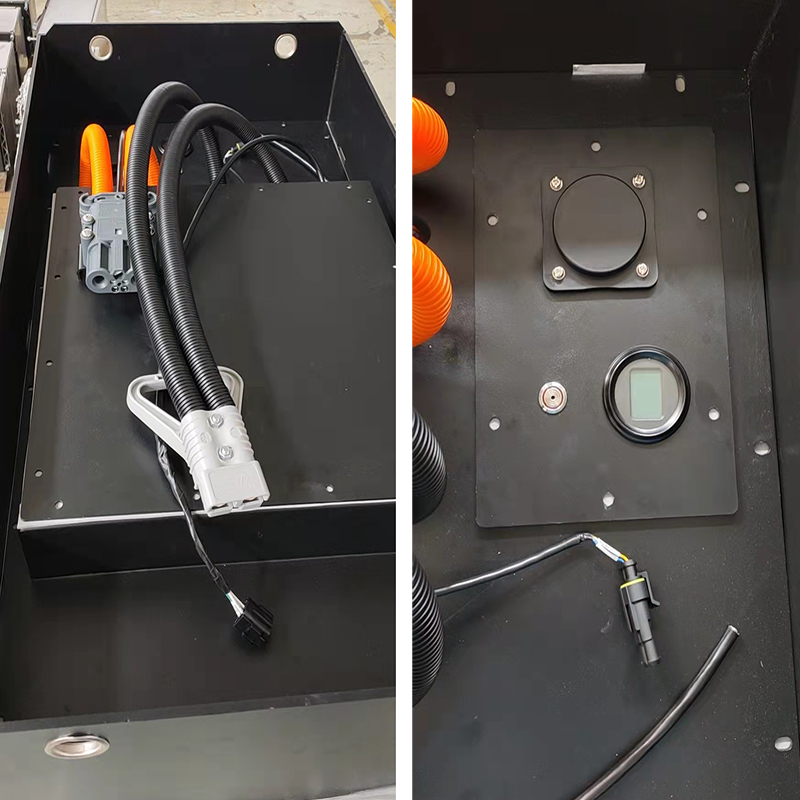

| Charge status display | Displayed on the external display and charger |

| Charging time | 120–180 minutes |

| Maximum charging voltage | 28.8V |

| Charging temperature | 0°C to 55°C |

| Discharging | Discharge temperature | –10°C to 55°C |

| Rated discharge current | 50A | 100A | 100A | 100A | 100A |

| Maximum discharge current | 100A | 200A | 200A | 200A | 200A |

| Discharge cut-off voltage | 22.4V |

Product Uses

The 24V Lithium Forklift Battery is versatile, powerful, and suitable for a wide range of industrial applications, especially in environments where forklifts, pallet jacks, and other material handling vehicles are used. Common applications include:

Electric Forklifts: The Lithium Ion Forklift Battery provides reliable and long-lasting power for forklifts, allowing them to operate efficiently with fewer battery changes throughout the day.

E-Trucks and E-Traction Vehicles: Whether you're using it for internal logistics or e-traction vehicles, the 24V Lithium Traction Battery offers robust power for electric trucks, ensuring reliable performance for demanding transport tasks.

Warehouse and Distribution Centers: In environments with high-frequency lifting, the forklift lithium battery ensures extended battery life, allowing for longer operational shifts and fewer downtime interruptions.

Material Handling Equipment: Powered by the advanced lithium-ion technology, this battery provides excellent power for various industrial equipment, contributing to more efficient workflows.

This high-performance battery can be used in a variety of forklifts and material handling equipment, providing both the power and durability needed to boost productivity while minimizing operational costs.

Product Operate Guide

Operating the Lithium Ion Forklift Battery is straightforward and user-friendly. Below are the essential steps to ensure safe and efficient usage:

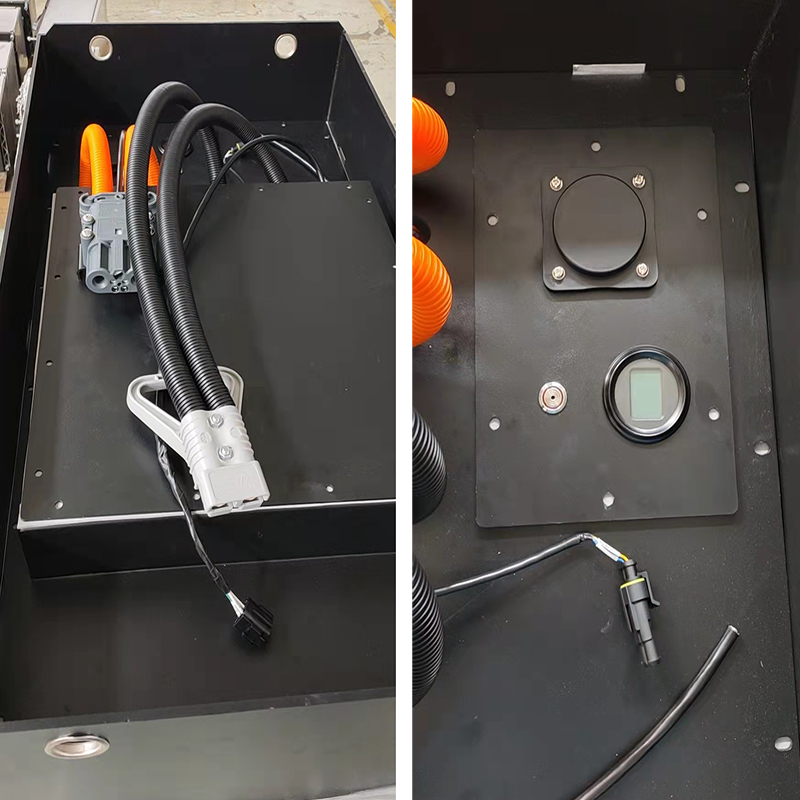

Installation:

The 24V Lithium Traction Battery is easy to install and is compatible with most electric forklift models. During installation, ensure proper placement in the forklift's battery compartment and secure all connections to avoid any damage. If you’re uncertain about installation, consult the manufacturer's manual or seek professional assistance.

Charging:

Charging the Lithium Forklift Battery is simple. These batteries come with a dedicated charger optimized for their high efficiency. Simply connect the charger to the battery and plug it into a power source. Since lithium-ion forklift batteries support quick recharging, you can top off the battery during short breaks, meaning you don’t have to wait for a full charge. For the best results, avoid overcharging and regularly check for any charging anomalies.

Safety and Maintenance:

One of the key benefits of lithium forklift battery safety is that there is no risk of acid leakage or harmful gas emissions, unlike with lead-acid batteries. However, to ensure safe operation, regularly inspect the battery for any signs of damage, corrosion, or irregularities. Keep the battery clean and free from debris, especially around the terminals.

Operating Conditions:

The Lithium Ion Forklift Battery is designed for optimal performance in a variety of working conditions. It performs well in temperatures ranging from -20°C to 60°C, but avoid exposing the battery to extreme environmental conditions for extended periods. Storing the battery in a dry, cool place can help extend its lifespan.

End of Life:

While lithium-ion forklift batteries typically last longer than their lead-acid counterparts, it’s important to monitor their performance over time. If you notice a significant drop in runtime or other performance issues, it may be time for a replacement. Ensure that any spent batteries are properly recycled at a certified facility to help reduce environmental impact.

Traction Battery vs Lithium-Ion Battery: Key Differences

When comparing a traction battery vs lithium-ion battery, it's important to understand the distinctions in performance, lifespan, and cost-effectiveness. While traditional traction batteries (often lead-acid-based) have been the standard in industrial environments for many years, lithium-ion batteries like the Lithium Ion Traction Battery offer a number of significant advantages:

Efficiency: Lithium-ion batteries offer up to 30% more energy efficiency compared to lead-acid forklift batteries.

Charging Speed: Lithium-ion batteries charge faster and can be recharged during short breaks, reducing the need for battery swaps.

Longevity: Lithium-ion batteries last up to 3 times longer than traditional forklift lead-acid batteries, offering a higher return on investment.

Safety: With no risk of acid leakage or gas emissions, lithium forklift batteries provide a safer operating environment compared to lead-acid batteries.