As the world moves towards cleaner and more sustainable energy sources, the forklift industry is also undergoing a transformation. One of the key areas of change is the transition from traditional lead-acid batteries to lithium-ion batteries. This shift is not only about reducing environmental impact but also about improving efficiency and reducing costs. In this article, we will explore the differences between lead-acid forklift batteries and lithium-ion forklift batteries, and how these differences can impact your business.

1. Understanding Forklift Batteries

Forklifts are essential tools in many industries, from warehousing to construction. They are used to lift and move heavy loads, and their efficiency and effectiveness are heavily dependent on the type of battery used. There are two main types of batteries used in forklifts: lead-acid and lithium-ion. Each has its own set of characteristics that make it suitable for different applications.

Lead-acid batteries have been the standard choice for forklifts for many years. They are well understood, widely available, and relatively inexpensive. However, they also have some significant drawbacks, such as limited lifespan and long charging times.

Lithium-ion batteries are a newer option for forklifts. They are more expensive upfront but offer several advantages over lead-acid batteries, such as longer lifespan, faster charging, and reduced maintenance. As the technology continues to improve and the cost of lithium batteries decreases, they are becoming an increasingly popular choice for forklift operators.

2. Lead-Acid Forklift Batteries: The Traditional Choice

Lead-acid batteries have been the go-to choice for forklifts for decades. These batteries work by using lead dioxide and sponge lead as electrodes and sulfuric acid as an electrolyte. When the battery is discharged, the lead dioxide and sponge lead react with the sulfuric acid to produce lead sulfate and water, generating electricity in the process.

One of the main advantages of lead-acid batteries is their low cost. They are widely available and relatively inexpensive compared to other types of batteries. They are also well understood, with a long history of use in forklifts and other applications.

However, lead-acid batteries also have some significant drawbacks. One of the biggest issues is their limited lifespan. These batteries typically last between 1,500 and 2,000 charge cycles, which can be a significant cost over time. They also have long charging times, often requiring several hours to fully charge. This can lead to downtime and reduced productivity in busy operations.

Another drawback of lead-acid batteries is their maintenance requirements. These batteries require regular watering to prevent the electrolyte from becoming too low, which can lead to damage and reduced performance. They also produce gases during charging, which can be hazardous if not properly ventilated.

3. Lithium-Ion Forklift Batteries: The New Contender

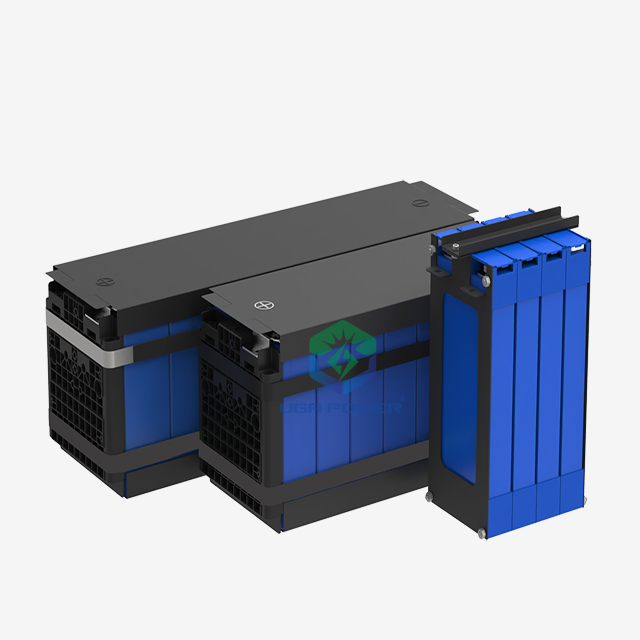

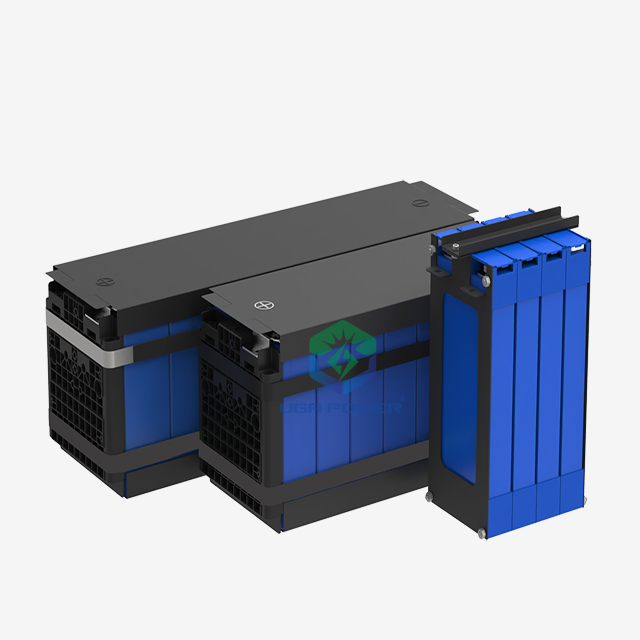

Lithium-ion batteries are a newer option for forklifts, and they offer several advantages over lead-acid batteries. These batteries work by using lithium cobalt oxide as a cathode and graphite as an anode. When the battery is charged, lithium ions move from the cathode to the anode and are stored there. When the battery is discharged, the lithium ions move back to the cathode, generating electricity in the process.

One of the biggest advantages of lithium-ion batteries is their longer lifespan. These batteries can last between 3,000 and 5,000 charge cycles, which can significantly reduce costs over time. They also have faster charging times, often requiring only 1-2 hours to fully charge. This can lead to increased productivity and reduced downtime in busy operations.

Lithium-ion batteries also have lower maintenance requirements compared to lead-acid batteries. They do not require regular watering and do not produce gases during charging, making them safer and easier to use. They are also more compact and lighter than lead-acid batteries, which can free up space and reduce the overall weight of the forklift.

However, lithium-ion batteries also have some drawbacks. One of the biggest issues is their higher cost. These batteries are more expensive upfront compared to lead-acid batteries, which can be a significant investment for some businesses. They also require specialized charging equipment, which can add to the overall cost.

4. Comparing Performance and Cost

When comparing lead-acid and lithium-ion batteries for forklifts, there are several factors to consider. One of the most important is performance. Lithium-ion batteries offer several advantages over lead-acid batteries, including longer lifespan, faster charging, and lower maintenance requirements. These advantages can lead to increased productivity and reduced downtime in busy operations, which can have a significant impact on the bottom line.

Another important factor to consider is cost. While lithium-ion batteries are more expensive upfront, they also offer several cost-saving advantages over time. For example, their longer lifespan means that they need to be replaced less often, which can reduce costs. They also have lower maintenance requirements, which can lead to further cost savings. Additionally, their faster charging times can lead to increased productivity and reduced downtime, which can have a significant impact on the bottom line.

However, it is important to consider the specific needs and requirements of your operation when choosing between lead-acid and lithium-ion batteries. For example, if your operation requires frequent charging or has limited space for battery storage, lithium-ion batteries may be the better choice. On the other hand, if your operation has a tight budget or requires specialized charging equipment, lead-acid batteries may be the more cost-effective option.

5. Conclusion

The choice between lead-acid and lithium-ion batteries for forklifts ultimately depends on the specific needs and requirements of your operation. Both types of batteries have their advantages and disadvantages, and it is important to carefully consider these factors before making a decision.

In general, lithium-ion batteries offer several advantages over lead-acid batteries, including longer lifespan, faster charging, and lower maintenance requirements. These advantages can lead to increased productivity and reduced downtime, which can have a significant impact on the bottom line.

However, lithium-ion batteries are also more expensive upfront and require specialized charging equipment, which can be a significant investment for some businesses. It is important to carefully consider the specific needs and requirements of your operation before making a decision.

In conclusion, both lead-acid and lithium-ion batteries have their place in the forklift industry, and the choice between them ultimately depends on the specific needs and requirements of your operation. By carefully considering these factors and weighing the advantages and disadvantages of each type of battery, you can make an informed decision that will benefit your business in the long run.